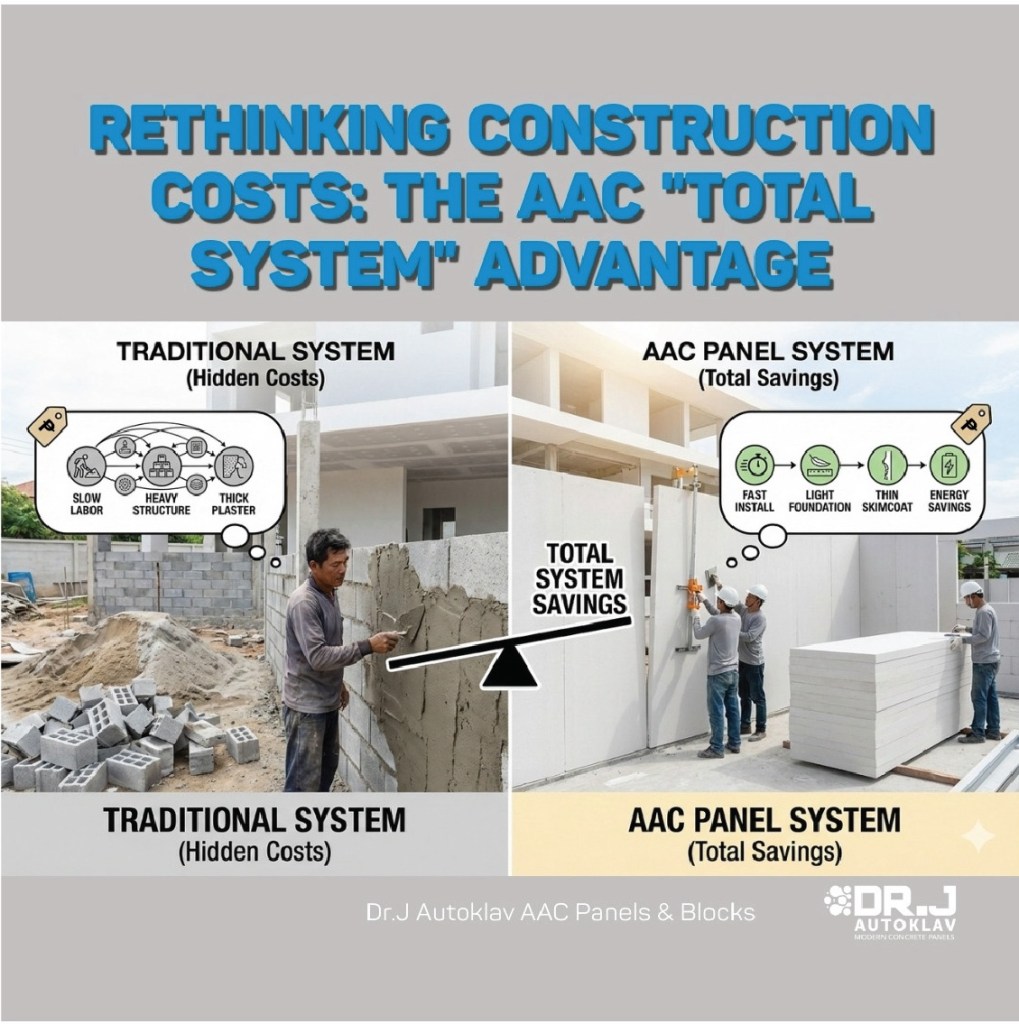

In construction, there is a common trap: focusing solely on the “sticker price” of a single material. While a pallet of traditional Concrete Hollow Blocks (CHB) may appear cheaper on an invoice than Autoclaved Aerated Concrete (AAC), looking at the price per block is like judging a car’s value only by the cost of its tires.

To find the true ROI, you must look at the Total System Cost. When you switch to an AAC system, you aren’t just buying blocks; you are buying a faster, leaner, and more efficient building process that can reduce overall project expenses by 15% to 20%.

1. Speed is Currency: Labor and Time

AAC blocks are significantly larger than traditional bricks but weigh up to 80% less. This “light but large” profile allows masons to build walls 2 to 3 times faster. Because the blocks are easy to saw, drill, and chase for utilities, the mechanical and plumbing phases are accelerated as well. In construction, every day saved on the timeline is a day saved on labor wages and equipment rentals.

2. The “Hidden” Structural Savings

Because AAC is so lightweight, it dramatically reduces the dead load of the building. For architects and engineers, this is a game-changer. A lighter building requires:

- Smaller structural steel members.

- Reduced concrete for frames.

- A less intensive (and therefore less expensive) foundation.

3. Precision Reduces Material Waste

Traditional blocks require thick, messy layers of mortar to account for uneven sizes. AAC is manufactured with high dimensional accuracy. They are joined using thin-bed adhesive (only about 3mm. thick), which uses far less material. Furthermore, the smooth surface of an AAC wall requires only a thin skim coat rather than a thick, multi-layer plaster, saving you a fortune on finishing materials.

4. Long-Term Operational Gains

The savings continue long after the builders leave. AAC’s microscopic air pockets provide superior thermal insulation, reducing HVAC energy consumption by 25% to 30%. When you factor in its resistance to fire, termites, and moisture, the lifetime maintenance costs drop significantly.

For more information about Dr.J AutoklavAAC contact Europhil Advanced Material & New Technology Inc. at 8Flr. Metrobank Plaza Bldg. Osmeña Blvd. Cebu City, +63997-216-0800, +63946-355-5501 or Unit 1717, Cityland 10 Tower 1, 154 H.V. Dela Costa, Makati, Metro Manila, Philippines. +63 920 983 1106

Leave a comment