Ancient Roman concrete has long puzzled scientists with its incredible durability, particularly in marine environments. Unlike regular concrete, which can deteriorate rapidly when exposed to seawater, Roman concrete has stood the test of time. This remarkable resilience is largely attributed to tobermorite through a chemical reaction between lime, volcanic ash, and seawater. This reaction is unique to Roman concrete and sets it apart from regular concrete.

Fortunately, the unique durability of Ancient Roman concrete is present in modern Autoclaved Aerated Concrete (AAC) which is a lightweight, energy-efficient building material that has gained significant popularity in recent years. One of the key factors contributing to AAC’s superior performance is the presence of tobermorite.

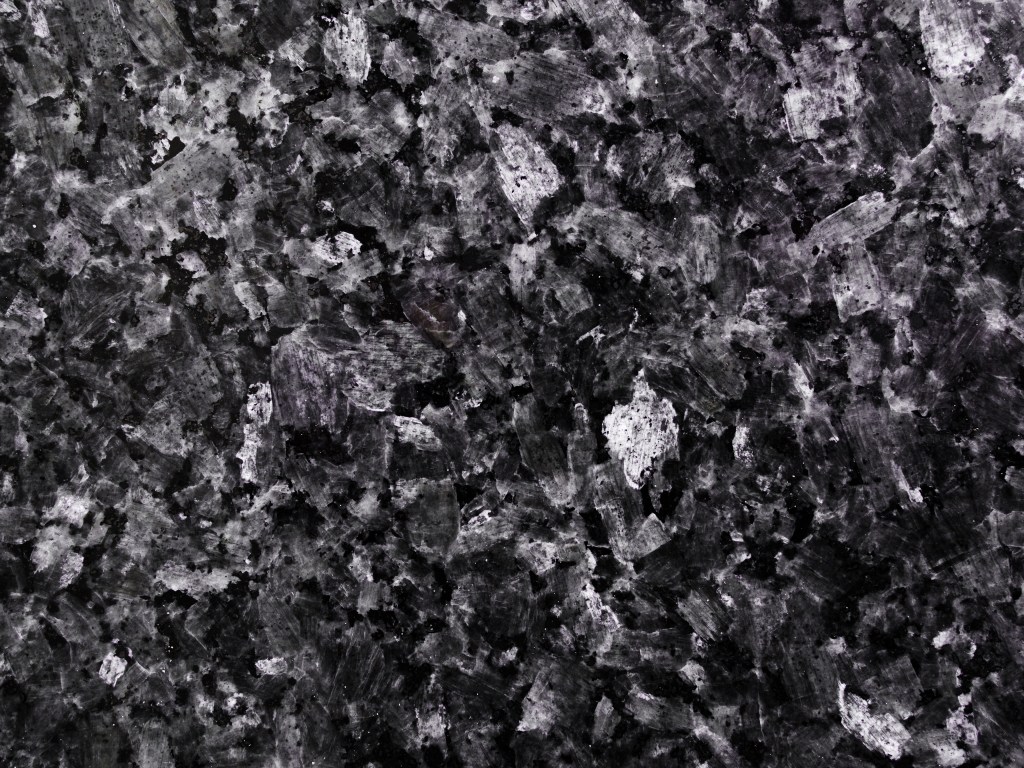

Tobermorite is a hydrated calcium silicate mineral that forms a strong, fibrous structure. It plays a crucial role in the autoclaving process used to manufacture AAC. During autoclaving, a high-temperature and high-pressure environment is created, facilitating the formation of tobermorite crystals within the concrete matrix.

The Benefits of Tobermorite: A Key Component of AAC

- Enhanced Strength: Tobermorite’s fibrous structure provides exceptional strength and durability to AAC. This allows AAC to be used as a structural material in various applications, including walls, floors, and roofs.

- Improved Thermal Insulation: AAC’s porous structure, combined with the presence of tobermorite, provides excellent thermal insulation properties. This helps to reduce energy consumption for heating and cooling, making AAC an environmentally friendly building material.

- Sound Absorption: Tobermorite contributes to AAC’s sound-absorbing properties, making it an ideal choice for noise-sensitive areas such as classrooms and residential buildings.

- Fire Resistance: AAC is naturally fire-resistant due to its non-combustible composition. The presence of tobermorite further enhances its fire resistance, providing added safety and protection.

- Chemical Resistance: Tobermorite is highly resistant to chemical attack. This is particularly important in marine environments, where salt and other corrosive substances can degrade concrete.

A More Sustainable Future

Tobermorite is an essential component of AAC, contributing to its exceptional strength, thermal insulation, sound absorption, and fire resistance. This valuable mineral plays a vital role in making AAC a sustainable and high-performance building material. This not only reduces the need for frequent repairs and replacements but also helps to minimize the environmental impact of the construction industry.

For more information about how AAC can be a modern solution to your construction needs contact Europhil Advanced Material & New Technology Inc. regarding Dr.J Autoklav AAC at 8Flr. Metrobank Plaza Bldg. Osmeña Blvd. Cebu City, or Unit 1717, Cityland 10 Tower 1, 154 H.V. Dela Costa, Makati, Metro Manila, Philippines. +63997-216-0800, +63946-355-5501 Email: info@DrJ-Autoklav.com

Leave a comment